Anderson-Cook’s Marand Model 200 Series Hydraulic

The Marand Model 200 spline rolling machine is Anderson-Cook’s cost-conscious workhorse. Simple, powerful, unidirectional hydraulic cylinders offer the quality, and repeatability that is inherent to the cold forming process. The Model 200 offers these advantages, the Anderson-Cook nameplate, and all with a lower initial investment.

The Marand Model 200 spline rolling machine is Anderson-Cook’s cost-conscious workhorse. Simple, powerful, unidirectional hydraulic cylinders offer the quality, and repeatability that is inherent to the cold forming process. The Model 200 offers these advantages, the Anderson-Cook nameplate, and all with a lower initial investment.

The model 200’s affordability does not translate into limited choices. Machine configurations of 230, 240, 250, 260, and 270 accommodate rack/tooling lengths of 24″, 36″, 48″, 60″, and 72″, respectively. (See table below for more details). Further customization is available for automatic parts loading, multiple rack/tool configurations, and quick-change fixtures. The 200 line accepts a variety of electrical power inputs, utilizes a self-contained oil or water based coolant system, and is of rigid cast iron design. And all Anderson-Cook spline rolling machines are built for ease of service.

Choosing a Machine

Machine choices usually “start with the part”. The part’s characteristics will typically determine the size machine needed. Our expert engineers can quickly and accurately assess your part’s requirements, guiding you to a machine ideal for your needs while avoiding the cost-overages of “too much machine.” One more way Anderson-Cook experience saves you money.

| 230 | 240 | 250 | 260 | 270 | |

|---|---|---|---|---|---|

| Overall Machine | |||||

| Height | 73″ | 73″ | 73″ | 73″ | 73″ |

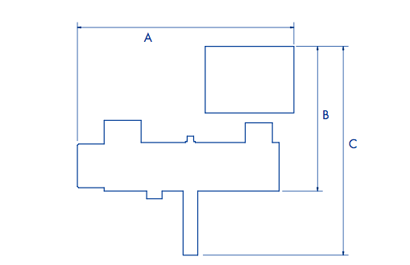

| Width (A) | 150″ | 170″ | 178″ | 186″ | 190″ |

| Depth (B) | 112″ | 112″ | 115″ | 115″ | 115″ |

| Depth with Overarm (C) | 174″ | 174″ | 178″ | 178″ | 178″ |

| Motor Size* | 25HP | 25HP | 40HP | 40HP | 50HP |

| Weight | 21,000 | 26,000 | 29,800 | 39,500 | 40,000 |

| Rack Holding Fixture Capacity | |||||

| Maximum Rack Size | 24″ | 36″ | 48″ | 60″ | 72″ |

| Fixture Width* | 3.63″ | 3.63″ | 4.75″ | 6.00″ | 6.00″ |

| Standard Daylight Opening* | 5.50″ | 5.50″ | 6.00″ | 6.00″ | 6.00″ |

| Max. Stroke of Slide | 30″ | 45″ | 57″ | 70″ | 82″ |

| Max OD of Work Part* | 2.0″ | 2.0″ | 2.5″ | 2.5″ | 2.5″ |

*Can be customized to suit the desired application